Week of 1/21/24

- lincolndbell9

- Jan 23, 2025

- 2 min read

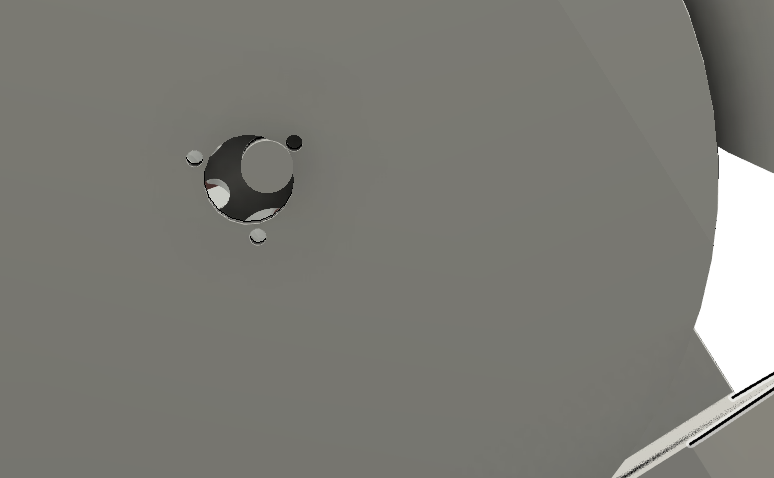

Last week, I was testing the new motor mounts by stacking both of my flywheels on one motor and testing the mounts with them. This worked great, and the flywheels ran smoothly with almost no vibrations(see last week's blog for video). Then, I reprinted the bed that the motors swiveled on, and moved on to testing with a flywheel on each motor and running them both at the same time. When I did this, I ran into a strange problem. When both of my flywheels were on just one motor, they would work perfectly, with almost no vibration. But when both motors were running with one flywheel on each, the vibrations came back. After some investigation, I noticed that my flywheels were spinning very slightly off-center. this meant that when they were spinning, the imbalance caused the whole rig to shake back and forth. When the flywheels are spinning at 3,000+ RPM, this shaking becomes a vibration, which is both very loud and unstable. I spent the last couple days trying to figure out why this issue was present when one flywheel was put on my motor, but not when two were mounted on the motor. I figured out that the issue was because the hole I drilled in the flywheel that slides onto the motor mounts was slightly bigger than the diameter of the motor mounts. This meant that the gyro had some wiggle room to slide off center when mounted, which is what caused the imbalance. The reason this wasn't an issue when both motors were stacked on top of each other is because the flywheels would slide in opposite directions, and the offset of one flywheel would counteract the other, canceling out the vibration.

Comments